in the present hyper-aggressive world current market, companies are regularly seeking strategies to further improve efficiency, minimize expenses, and sustain the best amounts of high-quality. regular ways of high-quality Command in many cases are time-consuming and susceptible to human error. This is when eyesight measurement machine suppliers are stepping in with ground breaking solutions which can be revolutionizing producing procedures. This article will delve into how Sophisticated eyesight measurement technologies, especially concentrating on Easson's cutting-edge 3-axis CMM equipment, is not just meeting latest calls for, but actively long term-proofing the whole production marketplace.

Table of contents:

AI Integration and Automation: another Frontier in Measurement

genuine-Time facts Analysis: reducing Downtime, Maximizing Output

Easson’s 3-Axis CMM: top the cost in Scalability and Adaptability

AI Integration and Automation: the subsequent Frontier in Measurement

The integration of synthetic Intelligence (AI) and automation is not a futuristic principle; it’s a current-day reality drastically boosting the capabilities from the eyesight measurement machine. AI algorithms empower these machines to find out from vast datasets, autonomously improve measurement parameters, and discover even quite here possibly the most subtle defects with unparalleled velocity and precision. This translates to a significant reduction in human intervention, minimizing the chance of mistakes and accelerating inspection times. automatic handling techniques even more streamline functions by seamlessly incorporating measurement processes into the present production line, causing a highly successful and optimized workflow. The improved throughput lets makers to meet demanding manufacturing schedules without compromising quality.

authentic-Time details Investigation: reducing Downtime, Maximizing Output

genuine-time knowledge analysis is proving to generally be a pivotal Device for manufacturers striving to minimize high priced manufacturing downtime. contemporary vision measurement units are actually equipped with sturdy software platforms capable of delivering fast and actionable suggestions on vital Proportions, tolerances, and process versions. This instantaneous information stream permits proactive identification of probable problems, like premature Device use, device calibration deviations, or product inconsistencies, extensive in advance of they escalate into major defects or catastrophic creation stoppages. By leveraging this actual-time intelligence, companies can put into action rapid corrective steps, enhance course of action parameters, and in the long run assure steady, uninterrupted production when reducing wasted methods and scrap substance.

Easson’s three-Axis CMM: primary the Charge in Scalability and Adaptability

Easson's three-axis CMM (Coordinate Measuring device) machines are at the vanguard of eyesight measurement technological know-how, featuring unparalleled scalability and adaptability to meet the evolving desires of recent production. These devices are meticulously engineered to accommodate a various array of part sizes, complex geometries, and different content types, building them ideally suited to a broad spectrum of manufacturing programs, from aerospace to automotive. As specific on https://zh-easson.com/products/visual-video-cmm-measurement-machine-with-3-axis-001%CE%BCm-linear-encoder, Easson's devices are renowned for his or her Extraordinary accuracy, boasting amazing 0.001μm linear encoders, guaranteeing the very best attainable standard of precision and repeatability. Their modular design and style facilitates seamless upgrades and customizations, making it possible for makers to adapt quickly to shifting output needs and technological developments with out incurring considerable funds expenditure. Also, Easson's unwavering determination to person-pleasant software interfaces and complete instruction courses ensures a seamless integration procedure and ideal utilization in their State-of-the-art engineering, empowering operators To optimize the device’s prospective.

In summary, vision measurement know-how signifies way over just a sophisticated good quality Command Resource; It's really a strategic essential for manufacturers seeking to long term-evidence their operations and maintain a competitive edge in the present demanding current market. By embracing the power of AI integration, actual-time facts Assessment, and remarkably scalable alternatives like Easson's State-of-the-art 3-axis CMM machines, companies can obtain unprecedented amounts of precision, greatly reduce downtime, enhance creation performance, and eventually drive major improvements in profitability. The strategic investment decision On this transformative know-how is not really simply a choice but a necessity for prolonged-time period good results. Take the proactive move to discover how Superior vision measurement alternatives can empower your business to thrive inside the at any time-evolving producing landscape, and get to out to some reliable eyesight measurement device supplier to debate your specific requires and prerequisites now.

Scott Baio Then & Now!

Scott Baio Then & Now! Tia Carrere Then & Now!

Tia Carrere Then & Now! Michael J. Fox Then & Now!

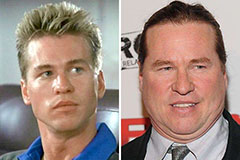

Michael J. Fox Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!